Factory Phone

+9821-56861646

Fax

+9821-56868523

Callphone

+989121753391

+989361010167

sangshekanpars

Impact Stone Crusher

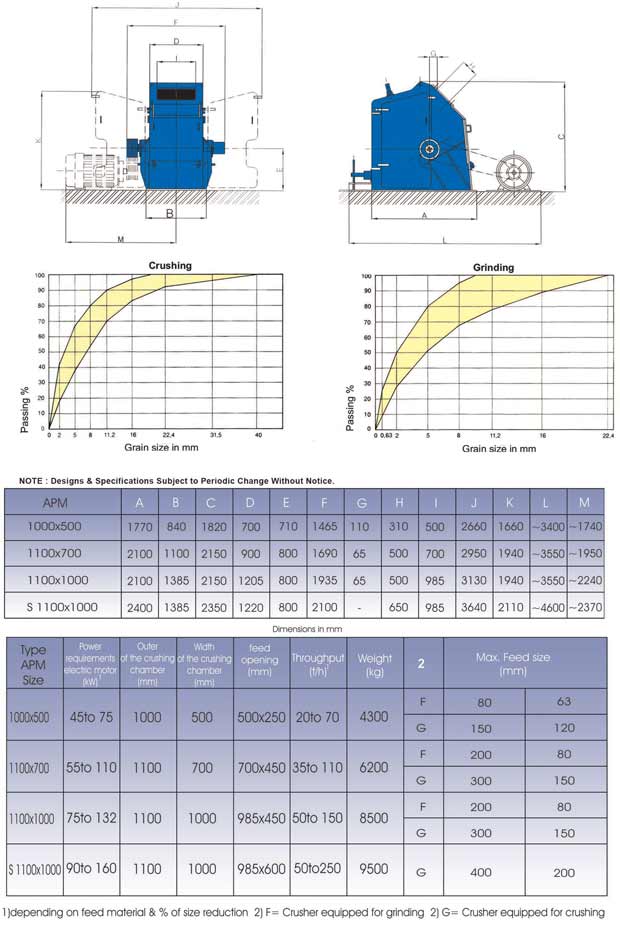

This machine is designed for crushing operations through the rotor. Kubits made in Pars Crusher Group are available in 80, 100, 120, 180, 240 and 450 ton models. Designed and manufactured in conventional and jacked type, both body types can be opened in two parts which can be replaced and operational upgrade of the device. Another advantage of the device is that it has an outlet load adjusting screw to control sand size.

Impact crusher is used as primary and secondary crusher in mineral processing lines, crushers consist of a rotor having 2 to 6 rows, a hammer blade and rotating at high speed. The role of the hammer blades is to throw the inlet parts (rocks and minerals) into the wall inside the crusher. On the inner wall of the crusher are a number of ribbed shields made of abrasion alloys that play the role of barrier and load components. The inlet is crushed by impact, the blades move at speeds of 15 to 50 m / s. In Pars crusher crusher, the output load grading is easily adjustable by the crusher regulated system.

Pars crusher crushers are manufactured in two types of hydraulic and plain type up to 240 tons per hour.

Parts supply: rifle, sandwich, hammer, hinge, rotor hinge, jack, switchgear, foliage, shaft, crank bearing, bearing, grease, spring in Iran and Middle East

Benefits of Impact Stone Crusher

• High crushing power

• Production of suitable polystyrene materials for concrete

• Easy maintenance

• The hammer can be adjustable

• Anchors can be re-ligated